Over time more and more traditional style lamps and house lights are being replaced with LED equivalents which are far more energy efficient with a longer lifespan. However while traditional Halogen bulbs are primarily a warm, comforting, almost amber shade of white, some Cool White LEDs have a more clinical, almost blue feel. We’ve heard these sometimes described as like a hospital or dentist waiting room, and not exactly a relaxing or comfortable home environment. It’s also a common complaint that cooler white LED lights have too much glare, we’ve also had customers whose newly fitted kitchen LED ceiling lights are too bright for them.

Quite simply, for most people, standard LED lights are too harsh.

Colour Temperature

Please note: Images on this page are intended to illustrate colour temperature, computer monitors can vary wildly in actual colour displayed, please do not attempt to colour match the temperature of your lights using the images on this page.

White light is measurable in terms of Colour Temperature and measured in Kelvin. This is a scale which ranges from lower numbers at the orange end of the spectrum to higher numbers at the blue end, with standard neutral white light being somewhere around 4500K. Although exactly how these exact figures translate to an indoors environment with other ambient or natural light sources can be a little subjective, they are a decent measurement for comparison.

Advances in LED technology have allowed more recent LEDs to become available in various preset Colour Temperatures, including a generic ‘Warm White’ which tends to be somewhere around the 2700K mark. In situations where it’s not easy or cost effective to replace the actual LEDs, a great alternative can be to use Lighting Gel to alter the temperature of your current lights.

Lighting Gel

Lighting Gel is a thin, non-adhesive, film-like material used traditionally in theatres to colour, diffuse, darken or otherwise affect the output of their theatre lights. Before mechanical moving head lights and digital based, colour-changing LEDs the best way to get a red light was to put a red Lighting Gel in front of a white light. Obviously there have been advances and changes within the industry but Lighting Gel remains very popular to this day due to its cost effectiveness and ease of use.

Lighting Gel is a thin, non-adhesive, film-like material used traditionally in theatres to colour, diffuse, darken or otherwise affect the output of their theatre lights. Before mechanical moving head lights and digital based, colour-changing LEDs the best way to get a red light was to put a red Lighting Gel in front of a white light. Obviously there have been advances and changes within the industry but Lighting Gel remains very popular to this day due to its cost effectiveness and ease of use.

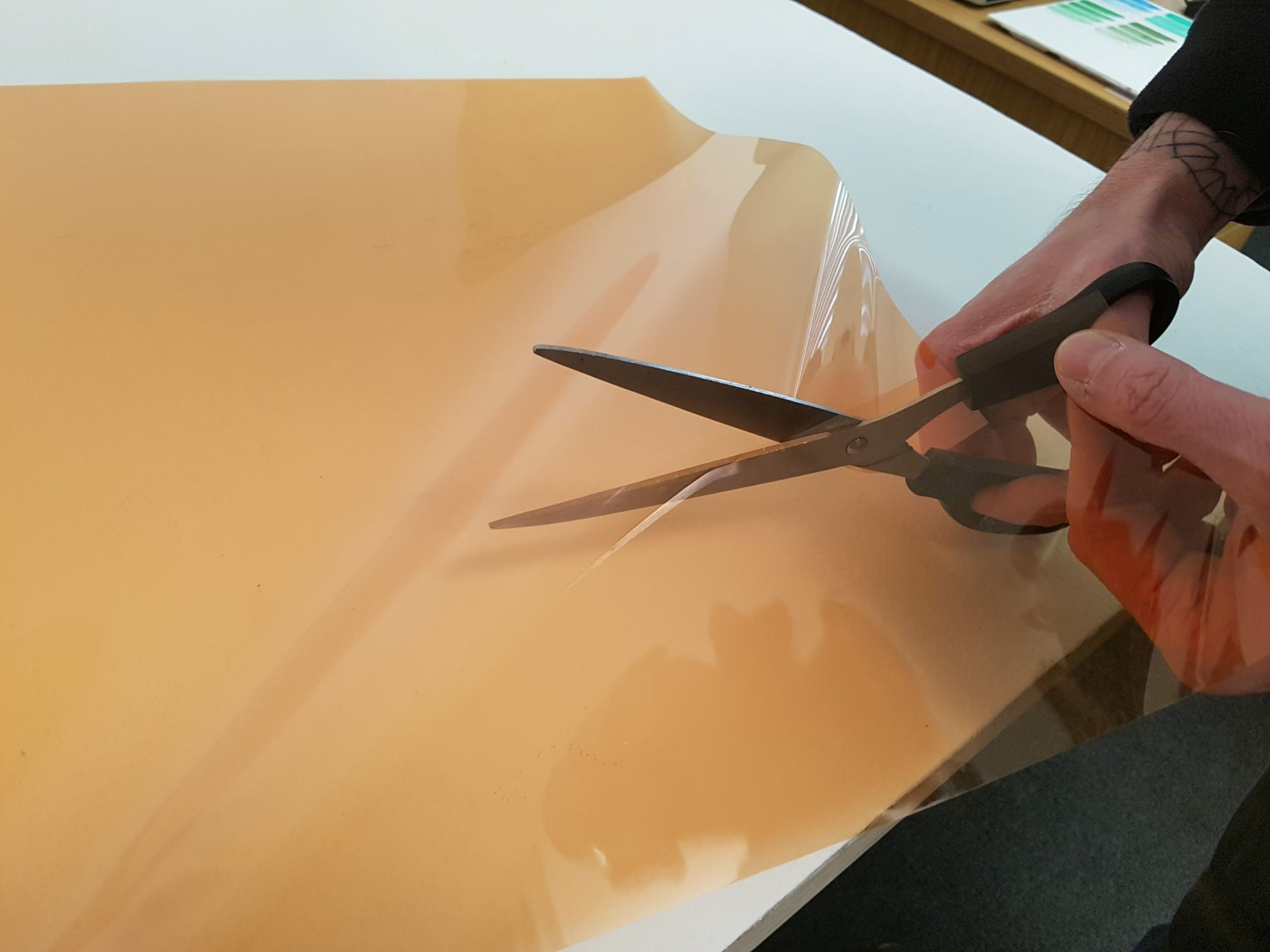

Lighting Gel from Rosco is available in two main types; the more cost effective E-Colour+ range which is a Surface Coated Polyester Film, and the more durable Supergel range which is a Body-Coloured Polycarbonate. For applications where the heat of the light itself is an issue (theatre lights can be upwards of 1000 Watt and can get very hot indeed!) then Supergel is the way to go, otherwise if the light itself doesn’t give off heat (as LEDs shouldn’t) then E-Colour+ would be suitable.

Warming Up Cool White LEDs

If you are looking to warm up LED Lighting then Rosco’s selection of specialist Colour Temperature Lighting Gels are perfect. These are designed specifically for warming up or cooling down the Colour Temperature of the light and are available in various strengths. The most popular for warming up Cool White lights are the Colour Temperature Orange (C.T. Orange) and Colour Temperature Straw Gels (C.T. Straw). These Gels are available in relation to the standard Full CT Orange as a half strength, quarter and one eighth strength CT Orange, and or extremely cold Colour Temperatures up to Double CT Orange.

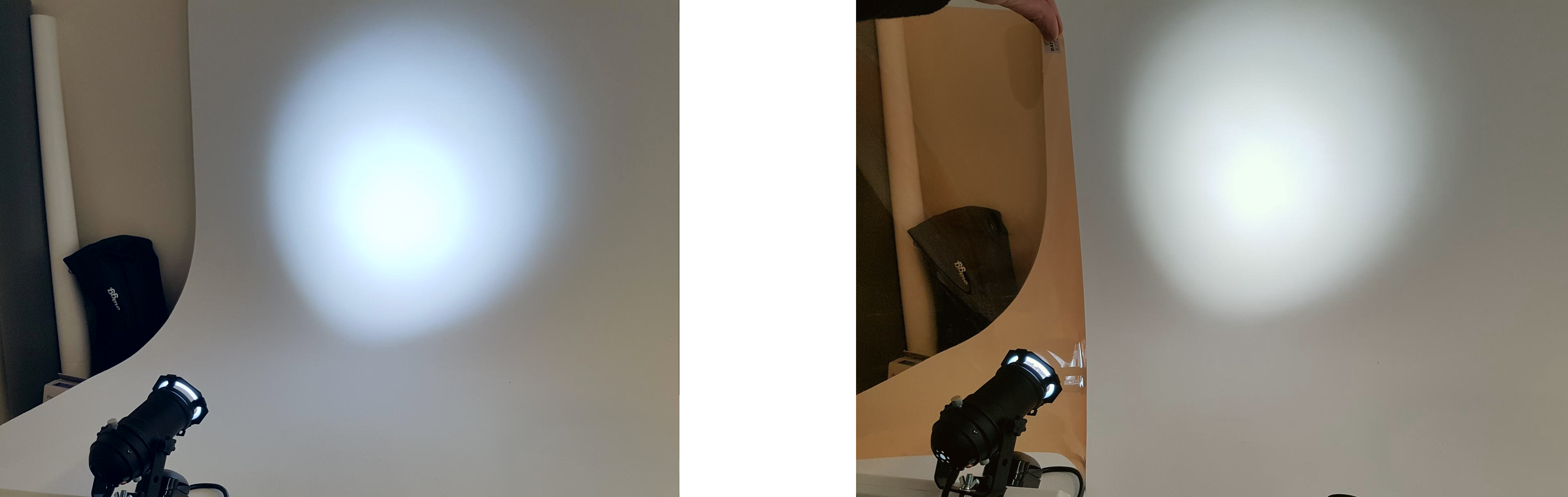

A fairly common Cool White LED is the GU10 base 3W Lamp from CED which has a colour temperature of around 6500K. As you can see in the photo below, this is a very harsh, almost blue-tinted white, and not a great relaxing colour for a home environment.

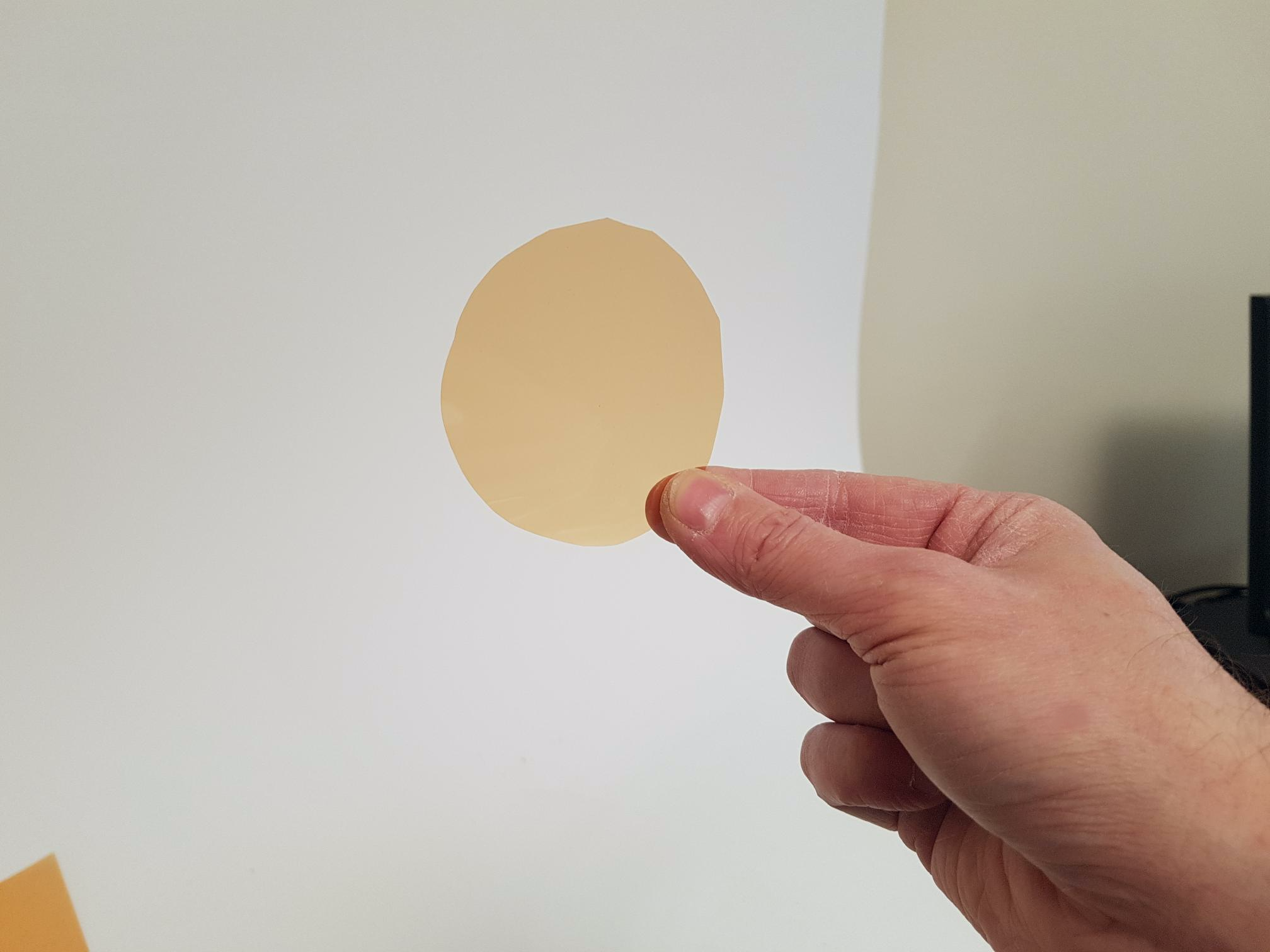

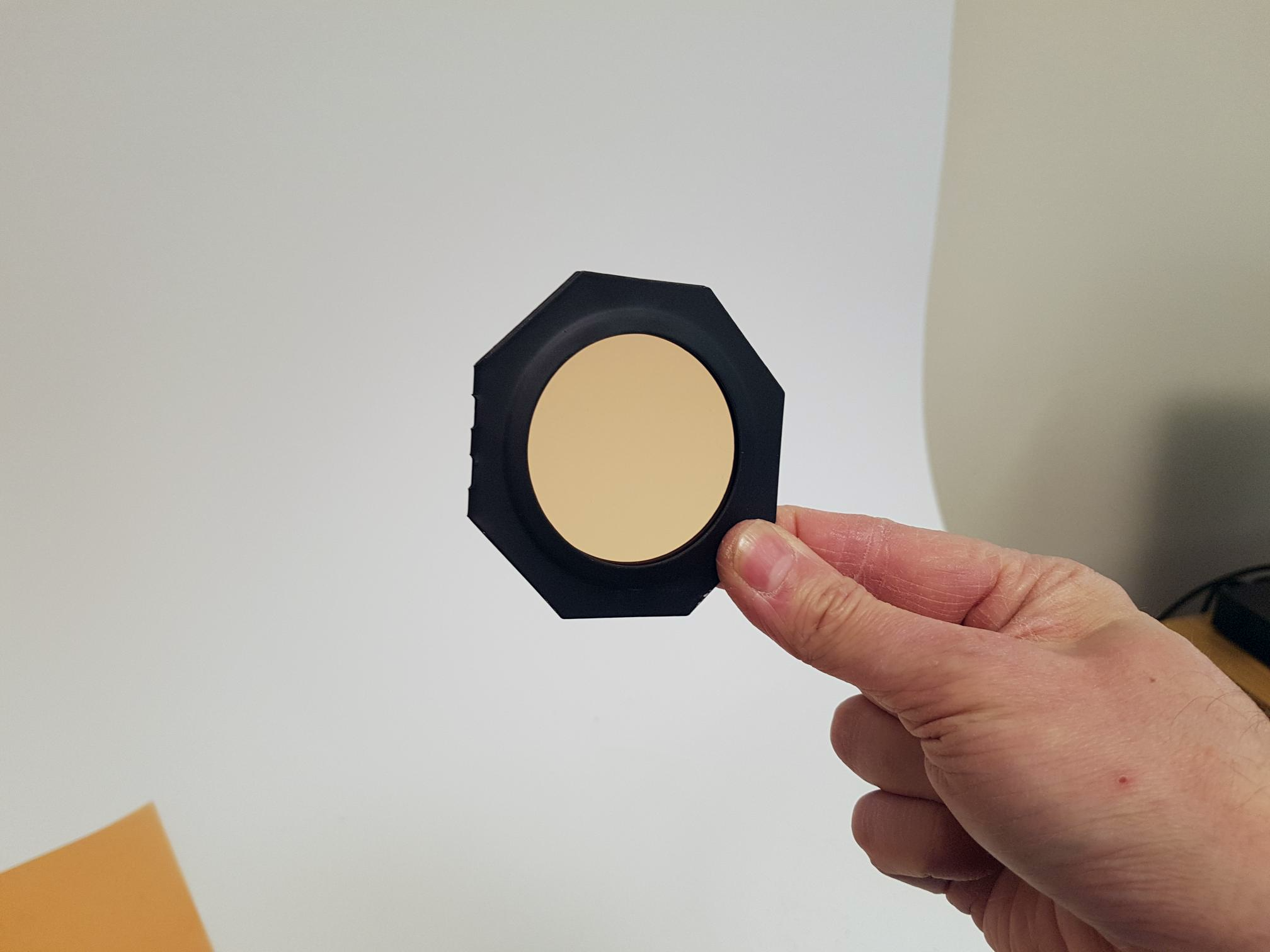

To bring this down to a more comfortable temperature closer to 2700K, you’d need a Gel like the 204 Full C.T. Orange Lighting Gel. This will bring the light output to just under 2700K, and is one of our most popular Gels for this exact purpose.

The above photos show the same Cool White LED rated at 6500K. The photo on the left shows the light shining as it would normally, and the photo on the right shows the light with a sheet of 205 Half C.T. Orange Lighting Gel held in front of it. This brings it down to 3800K which is a much more comfortable colour, although you can certainly go warmer than this by using stronger Gels or layering multiple sheets of Gel.

If you know the Kelvin of your source light as well as the range you are trying to get to, we can calculate the exact Gel or combination of Gels which will get you the closest to your preferred Colour Temperature. Unfortunately as the ‘perfect’ level of warmth is so subjective we can’t recommend one Gel over another otherwise.

If you don’t know the Kelvin of your lights then a little trial and error may be necessary, but a good starting point to test a few different strengths and tones of colour Temperature Lighting Gels would be our LED Warm Up Gel Kit

Lighting Gels can also be used with other light sources, including Halogens for the same purposes. But with any source other than LED, complications from heat or degradation over time are much more likely. It’s also worth mentioning that Gels will not work with most Sodium light sources as they do not produce a full spectrum of light and so cannot be filtered.

Installing and Fitting Lighting Gel

Once you’ve got your Lighting Gel, the actual way you put the Gel in place is likely to vary from one application to another. It is important to note that they are Non-Adhesive and will not simply stick to your lights, however we’ve heard of people having success clipping Gel into the housing of their lights, building a frame for the Gels, or using various tapes or glues to hold the Gel in place.

In any situation we always recommend keeping a few inches space between the light source and Gel, especially for non-LED applications, so that any heat given off from the light has space to disperse. You should also not cover any holes that exist in the light for the purposes of ventilation. As well as helping to minimise safety risks this will also prolong the life of the Gels.

While in an LED setting heat shouldn’t be an issue, Lighting Gels are designed as a consumable product for theatres and as such may degrade over time from complications arising from damp or other weather related issues, exposure to Sunlight or other UV light, or any other situation-specific conditions. That being said as long as the Gels are sufficiently protected otherwise then they should last a fair while, often longer than the lifespan of the bulb itself.